Linear Motion Design: Electric Actuators for Hydraulic Replacement

Introduction

Linear motion is an essential aspect of many industries, from manufacturing to automation. In the past, hydraulic systems have been the preferred option for linear motion control due to their high force output and fast response time. However, with the increasing demand for clean and efficient motion systems, over the last three decades, a new linear motion technology has emerged as a powerful contender to hydraulics. Electromechanical actuators are increasingly recognised for their superior performance, providing improved precision, flexibility, and reliability in many applications. With bore sizes ranging from 25.4 to 127mm and capable of exerting up to 222.4 kN of force, electric rod actuators are a viable alternative to hydraulic cylinders. By maximising energy efficiency and reducing maintenance costs, they also offer significant Total Cost of Ownership (TCO) benefits. This article provides a detailed comparison of the two technologies and offers valuable insights for converting from hydraulic systems to all-electric solutions.

1. Intro: Why electric?

Over the last three decades, technology for linear motion is being revolutionised by electromechanical actuators, which outperform hydraulic cylinders in terms of accuracy, adaptability, and dependability. Electric rod actuators are a cost-effective and efficient solution, lowering the total cost of ownership and requiring the least amount of maintenance, with bore sizes ranging from 25.4 to 127mm and up to 222.4kN of force. Our eBook compares the two technologies and offers helpful advice for switching from hydraulic to all-electric systems.

2. Hydraulics: No longer the only option

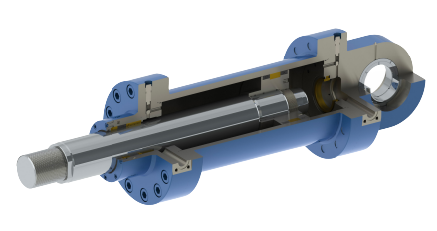

Hydraulic Cylinder

When it comes to industrial applications that require strong linear motion, hydraulic cylinders are the go-to-choice since they can swiftly and precisely move big objects in a straight line. These cylinders typically exert forces between 7.56 to over 7.56kN and have bore sizes between 2 and 20cm.

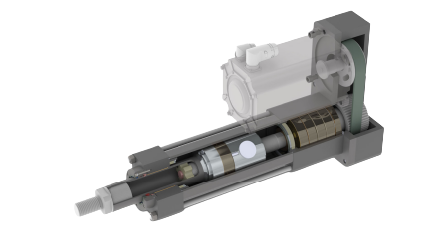

Electric Actuator

While hydraulic cylinders are known for their compact body, ruggedness, and cost-effectiveness, they also present long-term challenges and issues that operators are familiar with. Our solutions help address these issues and provide a more efficient and reliable alternative for high-force applications.

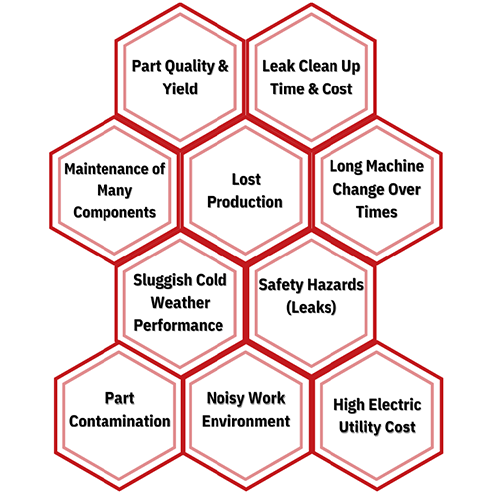

It’s not a matter of if but when hydraulic systems will leak or break. Clean-up is messy and time-consuming. When hydraulics fail, the production parts/ product may need to be scrapped out and production stopped while repairs and clean-up are undertaken.

In addition to the safety concern, hydraulics has slower productivity due to human changeover, a larger overall plant footprint, and ongoing maintenance of their numerous components. Data collection is difficult because of its noise, potential sensitivity to temperature changes, lack of accurate multi-position capability, and open-loop operation.

These drawbacks are enough for many engineers to look at alternative technologies.

Cons of Hydraulic Cylinder in Applications

3. Benefits of electric linear motion systems

Due to the higher versatility in motion control, engineers generally prefer electric actuators to hydraulic cylinders. Position control, velocity control, acceleration/ deceleration control, and complicated real-time control of motion variables are all made feasible by electric actuators, servo drives, and motor systems. This enables position control that is completely unrestricted and precision and repeatability levels that are superior to those offered by hydraulic systems.

Benefits of Electric Linear Motion Systems

Thrust capability –

Electric technology can achieve the same extreme forces as hydraulics. With easy-to-use motion control sizing software, actuator and servo component manufacturers make it simple to specify an electric system with equivalent thrust capability. Compared to electric actuators, hydraulic cylinders and their necessary components are more complicated.

Force control –

Electromechanical actuators with servo systems offer precise force control through constant monitoring of torque, which directly correlates to actuator force. Maintenance or system modifications are usually not necessary when force consistency is maintained within a single digit percentage point.

Position control –

Multiple positions can be easily achieved without the use of external sensors with closed-loop control. Settle time for these positions is quick and highly repeatable.

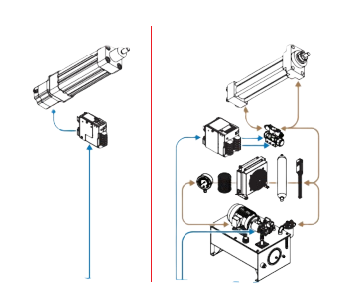

Hydraulic cylinders and required components (on the right) are more complex than electric actuators (on the left)

4. The total cost of ownership: The iceberg principle

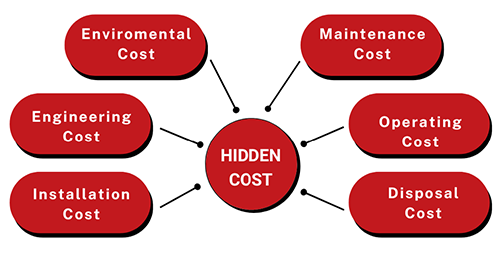

Hidden Costs on Using Hydraulics System

Engineers familiar with hydraulic systems may not fully realise the total cost of maintenance, scrap, and lost productivity. Although a hydraulic cylinder may appear to be less expensive than an electric actuator, the iceberg principle applies here as hidden expenses like installation, operating costs, disposal fees, and environmental costs add up to a system's total cost of ownership.

Even though electric servo systems could be more expensive to install than hydraulic systems, their long-term benefits make them a more economical choice. Electric systems have a cheaper total cost of ownership than hydraulic systems due to their superior accuracy, adaptability, and efficiency as well as their minimum maintenance needs over the course of the system's lifetime.

"Many leaks identified in hydraulic systems are left to drip away the profits of a company - profits lost with unnecessary energy consumption, reduced equipment performance, decreased reliability, increased fluid costs, increased housekeeping costs, etc."

Machinery Lubrication article – Detecting and Managing Hydraulic Systems Leakage

Why electric actuation systems can have a lower total cost of ownership compared to hydraulics:

Improved process control:

- Complete motion control flexibility

- Accurate and repeatable motion control

- Provide process optimisation

Improved reliability:

- A simplified electric actuator system

- Minimal to no maintenance

- Predictable, long, consistent life

Improved efficiency:

- High efficiency servo actuator system

- Power on demand

Improved risk mitigation:

- Clean electric actuator technology (no leaks)

- Safe working environment

5. Sizing and Converting Tips

Understanding three key variables is required when converting a hydraulic cylinder to an electric actuator system: force, motion profile, and electric actuator technology.

Converting a hydraulic cylinder to an electric actuator requires understanding the force being exerted by the hydraulic system, which is a function of hydraulic pressure. However, accurately measuring this force can be difficult, so the maximum-rated pressure of the hydraulic system is commonly used. Oversizing a hydraulic cylinder, on the other hand, is common and has a minor impact on the overall cost of the system. In contrast, oversizing electric actuators can significantly increase their cost. As a result, the process of calculating force should not be oversimplified.

The System Pressure Method, which applies the maximum rated pressure of the hydraulic system to the full piston area of the cylinder, is often used to calculate system capabilities but is not a complete solution for converting a hydraulic cylinder to an electric actuator.

Calculating using the system pressure method results in an over-sized, over-priced electric actuator solution

System Pressure Method: Not recommended

Force = Area of the cylinder X rated system Pressure

Because hydraulic systems are not always fully defined or known, engineers frequently apply conservative values and incorporate a factor of safety to ensure proper operation. This approach, however, may result in an over-sized and over-priced electric actuator solution. To prevent over-sizing, it's important to determine the true peak and continuous working force of the hydraulic cylinder. The best way to accomplish this is to record values of the application while in operation, which can be challenging, especially on an existing machine. Even if an exact pressure reading cannot be obtained, a pressure estimation within 15 percent of the actual force will provide a reasonable range.

The best way is to determine these application forces would be through the use of a load cell or the use of an electric actuator installed in the application. But this can be difficult or impossible to implement in existing machines or equipment.

The next best and most practical way is to measure hydraulic pressures in the cylinder while the process is in operation.

In general, pressure measurements can be taken in three different areas on a hydraulic system. The closer you can get to the work, the more accurate your measurement will be.

Three different areas on a hydraulic system to take pressure measurements

GOOD

Measure pressure at the valve. This is the most common for conversion applications. It is the furthest distance from the work point, which can increase error in actual vs. measured pressure.

BETTER

Measure pressure between the valve and the cylinder. Pressure may be affected by pressure compensated flow controls, needle valves, or other inline accessories.

BEST

Measure pressure at the cylinder. The most accurate location for reading pressure is closest to the point of work. This area may be the least accessible.

Conservative measurements will bring you close. Accurate measurements get you where you need to be so that actuators and motors aren't undersized or significantly oversized.

To size up the mechanical assembly and finalize motor and drive selection, take a video of the process in motion to learn how much time is needed to make the desired travel distance. Additionally, record any pressure gauges used in the application to better identify pressure spikes across the entire stroke that should be accounted for.

It is also important to note any process requirements that must be maintained, such as a constant velocity or a specific time to complete a move. An application sizing worksheet can be a useful tool to document these requirements and provide a quick snapshot of what is necessary for a specific application.

Most Accurate Method

We recommend that you measure not only the working pressure but also the return pressure in your system. Every hydraulic system is different. Return lines usually have little backpressure, but some systems can have a high return pressure between the cylinder and the valve. In these instances, the pressure does have an effect on the cylinder's output force (see the chart on the left).

The most accurate force calculations determine the dynamics on both the blind (piston) end and the cylinder rod end. When pressure is applied to a surface area, force is created. As a result, applying back pressure to the rod end of a cylinder during an extended move will offset some of the force used by the primary working pressure to the blind end of the cylinder. This must be considered. The Dual Force Method will be used to calculate these forces and the resulting force. The illustration on the right compares a relatively high back pressure with the primary working pressure.

6. Application example: Tube-Bending Machine

Why convert a tube-bending machine from hydraulic to electric

Tube-bending machines have been driven by hydraulics for the past 80 years because it has been the best way that manufacturers know to bend metal tubes. Hydraulic-driven machines can bend miles of tubing made of mild steel, stainless steel, copper, or aluminium at infinite angles, and create a variety of components used in different industries, from vehicle headrests to air conditioning heat-exchange pipes. Although there may be some waste, hydraulic-driven machines have been the industry standard for decades. The fundamental reason for using hydraulics is to make better parts.

But what if there's another option? One that makes better parts?

While hydraulic-driven machines have been the industry standard for tube-bending for decades, electric actuators offer significant advantages over hydraulic cylinders in terms of zero maintenance, longer life, no hydraulic fluid, efficiency, quietness, cleanliness, and accuracy. Despite these benefits, there are arguments against using electric actuators to bend tubes. For instance, electric actuators may take up more space next to the working area, cost more, and require training time and expense to adopt as a new technology. Operators may need to be convinced of the benefits of using electric actuators and the value of learning something new. However, if there's a better way that produces better parts, it may be worth exploring the benefits of electric actuators over traditional hydraulic systems.

Tube-bending Machine

Tube-bending Parts

The fundamental reason to consider changing to an electro-mechanical system: electric actuators make better parts than hydraulics.

When we say "better," we refer to producing less waste and achieving tighter tolerances, and electric actuators can help achieve this through force feedback. Force feedback enables the actuator to determine how hard it is pushing and coordinate the move with force and position, resulting in greater precision and control. This applies to tube-bending machines that make tubes used as structural members, such as vehicle roll cages, chassis frames, headrests, ornamental ironwork, awning frames, fence gates, furniture, and more, as well as tubes used for fluid transfer, such as heat exchangers for air conditioning or industries like petrochemical, automotive, and medical

How it works for head-rest tubing

The use of electric actuators in tube-bending machines can result in better parts with less waste and tighter tolerances. For example, in the production of head rests, electricweld tubing is used, which has loose tolerances for wall thickness and seam location, resulting in spring-back after bending. With force feedback from an electric actuator, the machine can adjust the actuator stroke for each bend, compensating for variations in tube thickness and seam location. This allows for tighter tolerances and less waste, reducing scrap by up to 80%. Overall, the use of electric actuators can help machine designers achieve better part quality and reduce material waste.

What's Next...

With their numerous advantages such as ease of installation, precision control, and reduced maintenance requirements, electric actuators have become a popular choice and a reliable and efficient replacement for hydraulic systems in linear motion design.

At Motion Control Products, we offer a wide range of electric actuators designed to meet the specific needs of our customers. Our products are built with the highest quality materials and are engineered to deliver exceptional performance and longevity. To learn more about our linear electric actuators and how they can improve your linear motion system, please visit our Linear Electric Actuators page https://motioncontrolproducts.com/mechanical/linear-electric-actuators.html