How a Harmonic Actuator Can Solve Your Problems and Simplify Your Design Projects

Introduction

We are seeing more and more demand for harmonic actuators, which are real problem solvers for our customers. Harmonic Actuators, also known as strain-wave gearing systems or harmonic drives, are ideal for applications where accurate and controlled positioning is needed at relatively low speeds. High torque duties are easily coped with. They are available as fully integrated solutions with motors, brakes, controllers and encoders provided where required. They are also compact, with complex duty requirements met within a small size envelope.

But there are many other applications and even the wheels on the lunar roving vehicle were powered by harmonic actuators, showing just hope adaptable they can be.

We frequently hear our customers are saying that due to their combination of high torque positioning, at low speeds with zero backlash, a harmonic actuator has saved having to have a development project.

1. Intro: Our Harmonic Range and Capabilities

2. Harmonic Actuators: Benefits

3. Low Cost of Ownership

4. Harmonic Actuators: Applications

5. Harmonic Actuators: How do They Work

6. Harmonic Actuators: A Fully Integrated Solution

7. In Summary

1. Intro: Our Harmonic Range and Capabilities

- Peak torques up to 800 Nm

- Speeds vary, typically up to 100 rpm

- Continuous torque up to 557 Nm

- Hollow shaft diameter 9 to 45mm

- High reduction gearing with gear ratios from 51 to 161 to one

- Motor voltages 48 VDC, 110 or 220 V AC

2. Harmonic Actuators: Benefits

Harmonic actuators offer a high torque, minimal backlash, compact and fully integrated drive system. They are maintenance free and available with ingress protection to IP67. The Harmonic actuator is also smooth and quiet, which is important in many applications. Any alternative approach to this, involving gearboxes and complex components, can be bulky, expensive and end up as a development project. Getting conventional gearboxes with the sorts of ratios that harmonics offer and minimal backlash, really isn’t straightforward as backlash increases with multiple stages, making the advantages of the harmonic actuator overwhelming in a lot of applications.

3. Low Cost of Ownership

Harmonic actuators offer a low cost of ownership for a wide range of reasons:

Maintenance

- No gearbox lubrication

- Leaks Eliminated

- No periodic maintenance

Fully Integrated Solution

- Reduced development risk

- Reduced project cost

- Reduced project time

Compact Size

- Reduced cost of containment and machines

- On going savings from reduced weight and size

4. Harmonic Actuators: Applications

The joints in robotic arms and precision CNC applications make the most used of the precision nature of harmonic actuators and the lack of backlash.

Placing of electronic components is also an important application. For this type of application, the lack of vibration associated with harmonic actuators is an advantage.

Very low speed precise control is required for many medical devices such as MRI and CAT scanning machines or surgical tables. Harmonic drives are ideal for these applications where their quiet operation is also a benefit.

These are just a few of the important applications for harmonic actuators, but we are finding more as the drive’s benefits become clear.

5. Harmonic Actuators: How do They Work

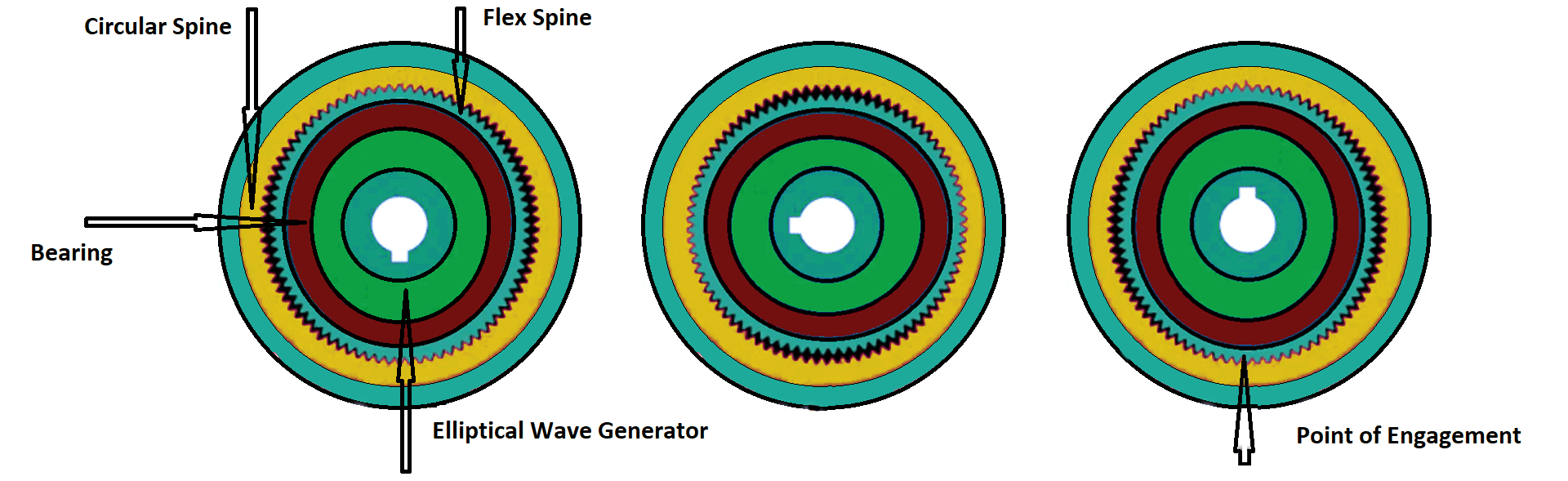

The Harmonic Actuator consists of three parts. There are two gears, called the flex spine and the circular spine. The circular spine is an internal gear. The flex spine is an external gear with slightly fewer teeth. As the name suggests, it is flexible. Its shape is formed by the third part, the wave generator, which has an elliptical shape and sits inside it. The two gears engage at two points opposite each other, corresponding to the peaks of the wave generator ellipse. The wave generator is rotated, normally by an electric motor. As the wave generator rotates, the flex spine will rotate in the opposite direction and at a far slower rate. The overall gear ratio is determined by the difference in number of teeth between the circular spine and the flex spine. The lack of backlash comes from the way that the wave generator slightly forces the engagement of the two gears.

Very high reduction ratios are possible and the resulting product is very compact compared with a conventional gearbox, and will frequently show efficiency benefits too.

6. Harmonic Actuators: A Fully Integrated Solution

Our harmonic actuators can be supplied as a fully integrated solution. The following are available:

- IP67 brakes are also available where required (The gearboxes are back driveable, so a brake is required by some customers).

- We can supply integrated control systems supporting either CANOpen or Ethercat.

- Incremental or absolute encoders.

7. In Summary

We’re really excited about the solutions that harmonic actuators can offer. Their ability to solve problems and simplify projects is welcomed by many of our customers who find that their quiet, smooth, backlash free operation and precision control is exactly what they need for their projects and products.

What's Next...

If you feel this article is useful and would like to know more about the actuator itself, at Motion Control Products we provide a variety of harmonic actuators tailored to fulfill the unique requirements of your applications. Our harmonic actuators are manufactured using top-notch materials and are designed to deliver outstanding performance and durability without breaking the bank. If you are interested in learning more about our harmonic actuators and their potential to enhance your motion control project, please visit our Harmonic Actuators page:

If you would like to talk to our technical team about sizing and selecting a proper harmonic rotaory actuator model for your appliactions and design, please contact us at (+44) 01202 599922 or by email [email protected]