Printing And Packaging

The huge volumes of product involved in the printing and packaging industries have driven an ever increasing focus on cost, reliability and precision. Public awareness of the problem of packaging disposal puts sustainability at the forefront with the focus on the issue of waste, which is so closely linked to cost issues.

Traditional packaging machinery was often pneumatic. Such systems can be fast and powerful, but the whole process of pressurising air, storing it and using it to drive machinery is fundamentally inefficient. The use of electrical systems is always going to require less energy, and offers additional advantages of control. Put simply, with a pneumatic system, the air pressure is applied and the device is actuated; with an electrical system, there is a lot more control. The use of electrical systems with encoder feedback, and the use of a drive system, allows speed, acceleration and position to be maintained as required. This can result in reduced energy demand and optimised timing to save overall process times. This shift towards digital control of packaging processes is now unstoppable and is giving improvements throughout processes.

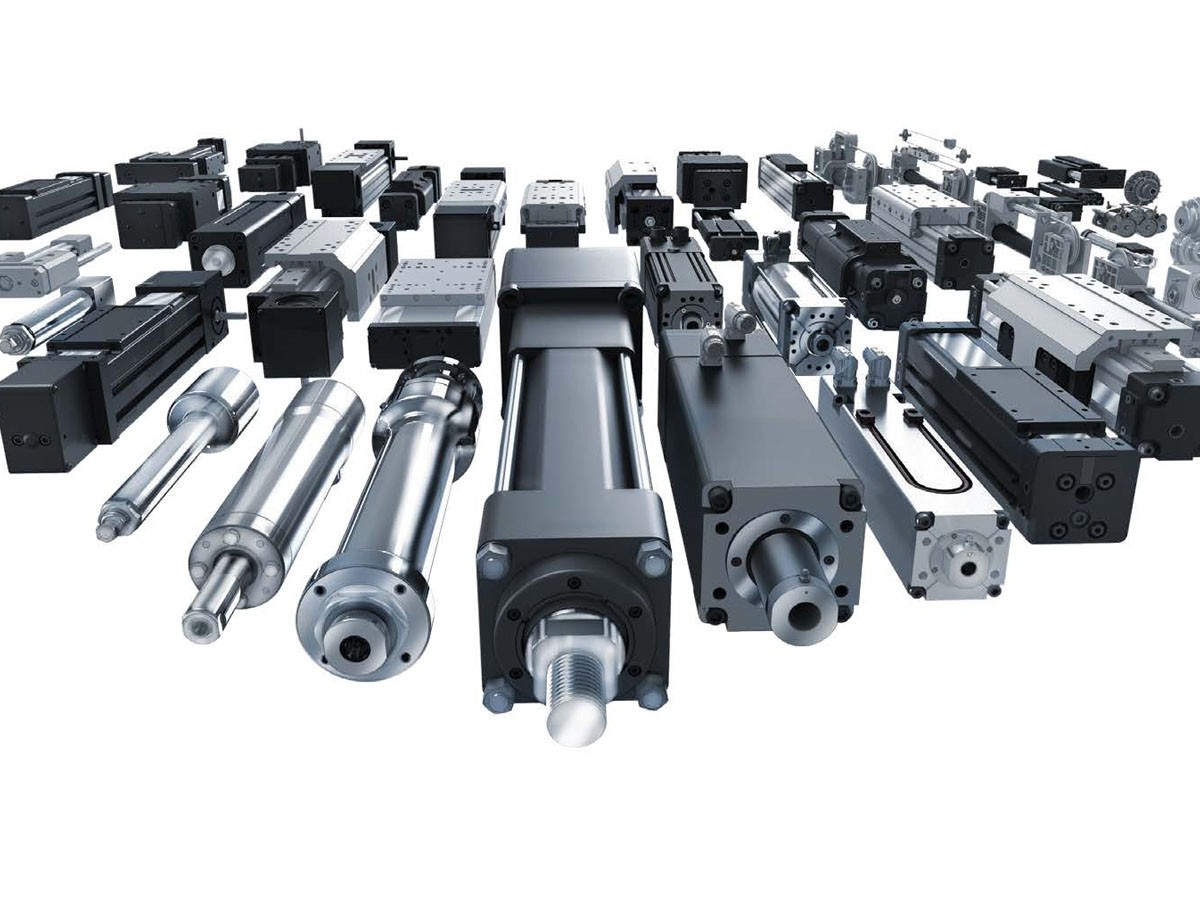

Feedback is vital for controlling position in printing and packaging applications. We supply a wide range of rotary and linear encoders which give positional feedback. We supply drives which give torque control, which is useful for many operations even as apparently simple as fitting lids and covers.

Our ranges of linear actuators are also widely used in the printing and packaging industries. These products are well suited to flexible applications as their stroke can easily be varied. A good example of a requirement for flexibility is applications where boxes are actually sized for individual consignments to optimise size. That’s one way of getting over the scenario of a USB cable turning up in a massive box!

Our linear track motors will drive packaging processes very efficiently. Moulded racks allow long lengths of travel, and our magnet-free track helps keep costs down, especially for longer tracks. The absence of magnets in the track also helps with EMC issues.

We also believe that our MMF3 linear motor will have potential for use in the printing industry for Magnetic Ink Character Recognition (MICR) applications. This is a technology frequently used for reading information on cheques and other financial documentation. It is a high speed and high accuracy reading technology, generally used by the banking industry and is significantly quicker than Optical Code Recogntion (OCR). It can still be read by humans, unlike bar codes. The ink involved carries iron oxide particles.

Modern printing machines frequently use linear motors. Traditional linear motors have large numbers of magnets built into the track and stray magnetic fields can present a problem for the magnetic inks, causing quality issues with the resulting prints.

Our MMF3 linear motor does not incorporate any magnetic material in its track. We believe that this offers a potential solution to the problem of stray magnetic fields in the printing process. The absence of magnetic material in the track also minimises the use of rare earth materials for a more sustainable solution.

Used with a linear encoder alongside the track, our MMF3 linear motor represents a highly accurate cost effective solution to linear motor requirements. With a maximum speed of more than 18 metres per second, it is capable of the most demanding printing applications. Please watch our Youtube video "Your All-In-One Solution to conquer Ink Migration" to find out more details.

Speak to us if you believe that our MMF3 Magnet Free Track Linear motors might be of assistance in your applications.

Your All-In-One Solution to conquer Ink Migration

Flexibility is key for the printing industry. A lot of printed material is now printed on demand, with continuous variations in the product. The savings in capital, space and waste are considerable. Digital control has transformed the printing industry.

At Motion Control Products, we assist with all your printing and packaging needs. Watch the video on the right to see how our products optimise operations for cost-effective, sustainable solutions.

Feel free to contact us for further assistance.

Ready to find out more? Contact us for a quote.

Please contact our technical sales team for pricing, datasheets, technical drawings (2D / 3D), hardware & software manuals or any other technical information for your applications...